Mesh: Checking the Mesh Quality

Use the field function and tools available in Simcenter STAR-CCM+ to check the quality of the generated mesh.

The volume mesh generated in the previous tutorial appears fine at first glance, however, to check the mesh quality properly, use the tools available in Simcenter STAR-CCM+.

To check the quality of the mesh:

-

Launch

Simcenter STAR-CCM+ and load

foundationTutorial_8.sim.

You can either use the sim file that you saved from the previous tutorial, or load the sim file provided in the tutorials bundle. See Downloading the Tutorial Files from the Support Center Portal.

- Save the simulation as foundationTutorial_9.sim.

-

Run the included Java macro to check the quality of the mesh:

-

In the

Macro toolbar, click

(Play Macro).

(Play Macro).

- In the Open dialog, navigate to [INSTALL_DIR]/doc/startutorialsdata/foundationTutorials/data, select checkMeshQuality.java and click Open.

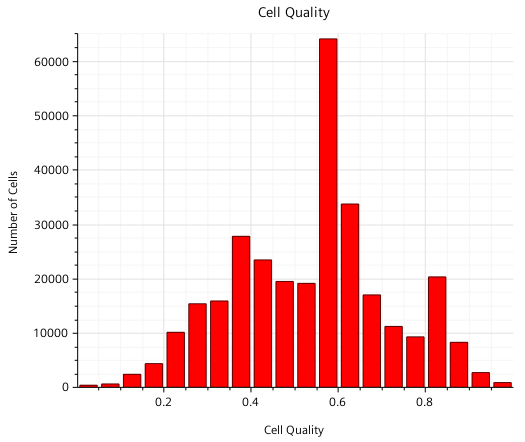

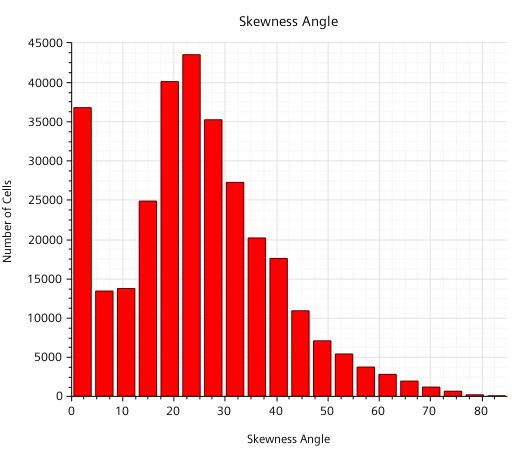

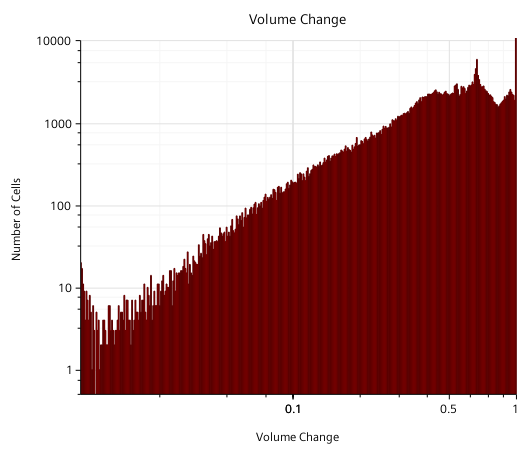

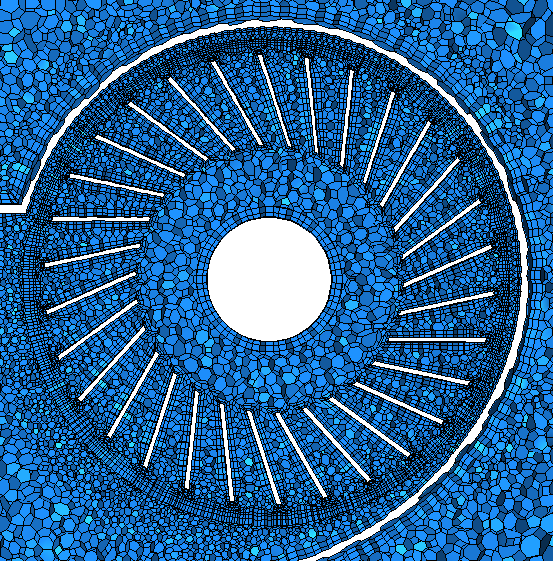

The macro sets up mesh quality plots. The cell quality, cell skewness angle, and volume change are displayed in histogram plots. The plots are opened automatically after running the macro. The macro also sets up derived parts and scenes to help you visualize the mesh and the mesh quality inside the scenes. -

In the

Macro toolbar, click

-

View the histogram plots:

-

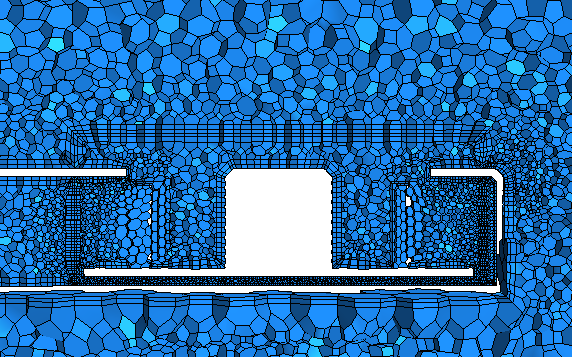

View the mesh quality scenes:

In general, the quality of the mesh inside the rotating region needs refinement to help achieve a more accurate solution. Prism layers are generated on the interface between the static region and rotating region, when they are not needed. The prism layer is not generated on the bottom surface underneath the fan. It is important to have prism layers in this area. The prism layers around the fan blades are too large to resolve the velocity gradient accurately.

- Save the simulation.