Prepare the regions for the simulation domain and select the meshers.

Begin by creating the regions:

-

Launch

Simcenter STAR-CCM+ and load

foundationTutorial_7.sim.

-

Save the simulation as

foundationTutorial_8.sim.

-

Create the regions from the geometry parts:

-

If the geometry scene is not open, double-click the

node.

-

Expand the

node.

-

Select the

Rotating Region and

Static Region nodes.

-

Right-click on a selection and choose

Assign Parts to Regions....

-

In the

Assign Parts to Regions dialog, select:

- Create a Region for Each Part

- Create a Boundary for Each Part Surface

- Create Contact-mode Interfaces From Contacts

- Click

Apply then

Close.

The geometry in the scene changes to a dark gray color to show that parts displayed in the scene are assigned to regions. Parts that have no region association are displayed in a light gray color.

-

Create an automated mesh operation and select the mesh models:

-

Right-click the

node and select

.

-

In the

Create Automated Mesh Operation dialog:

- Select

Rotating Region and

Static Regon from the

Parts list.

- Select the following meshers, in order:

| Group

|

Mesher

|

| Surface Meshers

|

Surface Remesher

|

| Core Volume Meshers

|

Polyhedral Mesher

|

| Optional Boundary Layer Meshers

|

Prism Layer Mesher

|

The Surface Remesher retriangulates the surface of the geometry and improves the overall quality of the initial surface. The Polyhedral Mesher generates polyhedral cells that are suitable for turbulent and swirling flow simulations. The Prism Layer Mesher generates a prism layer (orthogonal prismatic cells) next to wall surfaces or boundaries. Prism layer cells are important for resolving the boundary layer and the velocity gradient of the flow near surface.

-

Click

OK.

An automated mesh operation,

Automated Mesh, is added to the

Operations node. The mesh models that you select are located inside this operation under the

Meshers node.

-

Set up the mesh parameters:

-

Expand the

node.

The global mesh parameters are located under this node.

-

Select

Base Size and set

Value to

2 mm.

The base size is the reference length for all reference size controls. Using the value that you specify in the base size, you can scale the mesh using relative size controls as a percentage of the base size, or set these controls independently using absolute values. Typically you set the base size to the scale of the object of interest, in this tutorial this is the fan blades in the graphics card.

-

Select the

Target Surface Size node, select

Relative to Base and set

Percentage of Base to

1000 in the Properties Window.

The target surface size is set as a percentage of the base size and specifies the cell size that the meshers should aim for when generating the mesh. The target size can be smaller or larger than the base size, and you can use it to grow or shrink the cells in the mesh.

-

Select the

Minimum Surface Size node, select

Relative to Base and set

Percentage of Base to

50 in the Properties Window.

The minimum surface size specifies the smallest element size that the mesher can generate. The thickness of the fan blade is 1 mm, while the base size is 2 mm. Setting the minimum surface size to 50% of the base size returns 1 mm and allows the mesh to capture the details of the fan blades.

-

Select the node, set Size Type to

Absolute, and set Absolute

Size to 2 mm in the Properties Window.

By default, all size controls are set as a percentage of

the base size. By setting the size type to absolute, you make this

property independent of the base size. Absolute values are useful when

you want to have full control over the size of a particular setting.

Boundaries in the simulation regions affect how the mesh is generated. More specifically, prism layers are generated next to wall boundaries and interfaces (the contacting surface between the regions). The far field walls of the simulation domain (the walls that are far away from the object of interest) are not important for this simulation; however, for the purpose of this tutorial, the size of the simulation domain is smaller than what is recommended for industrial cases. Ideally the far field surfaces in the simulation domain should be further away, as having these surfaces close to the geometry of interest will affect the flow inside the simulation domain. One way to reduce the effect of the walls on the overall flow inside the simulation domain is to set the outer surfaces to symmetry boundaries. Prism layers are not generated on symmetry boundaries.

-

Set the walls of the simulation domain to symmetry boundaries:

-

Expand the

node.

-

Select the

Block.Block Surface,

Block.Downstream, and

Block.Upstream nodes and set

Type to

Symmetry Plane.

The selected boundary surfaces change to a blue color in the geometry scene to indicate that they are symmetry boundaries.

-

Save the simulation.

-

To generate the volume mesh, right-click the

Automated Mesh node and select

Execute.

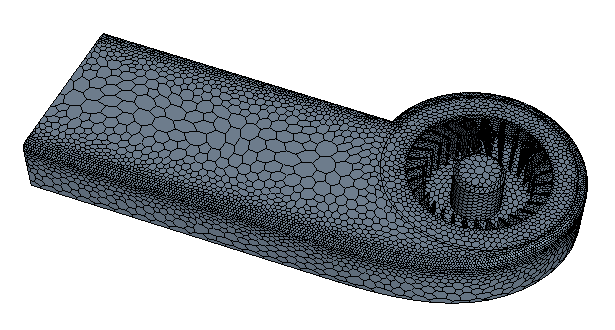

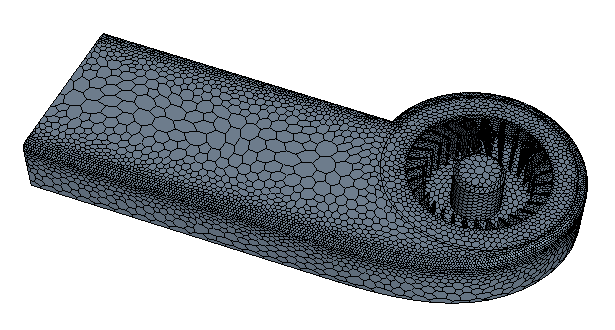

The surface remesher retriangulates the initial geometry surface tessellation into more evenly sized triangles. The space for the prism layer is calculated and reserved, this is called the prism layer subsurface. The polyhedral mesher creates three-dimensional cells, called tetrahedra, from the retriangulated surface and converts them to polyhedra. The prism layer is then generated and fills the reserved space with prism layer cells.

-

Create a mesh scene to visualize the mesh:

-

Right-click Scenes and select .

-

Rename the

node to

Simulation Domain.

-

Create another mesh scene and rename it to

Fan and Enclosure.

-

Click

Scene/Plot above the simulation object tree.

-

Double-click the node.

-

In the

Parts dialog, right-click on a blank area of the dialog and select

Deselect All to clear the selection.

-

In the same dialog, expand the

Regions node.

-

Select the

and

.

-

Click

OK.

The cell size automatically adjusts, within the specified parameters, to capture the shape of geometry.

-

Save the simulation.