Multiphase flow is a term which refers to the flow and interaction of

several phases within the same system where distinct interfaces exist between the phases.

Simcenter STAR-CCM+ considers flow options where phases coexist

as: gas bubbles in liquid, liquid droplets in gas, and/or solid particles in gas or liquid,

and/or (large scale) free surface flows.

The term ‘phase’ usually refers to the

thermodynamic state of the matter: solid, liquid, or gas. In modeling terms, a phase is

defined in broader terms, and can be defined as a quantity of matter within a system

that has its own physical properties to distinguish it from other phases within the

system. For example:

- Liquids of different density

- Bubbles of different size

- Solid granules of different

size and/or weight

Multiphase flows are different from

multi-component flows. In multi-component flows, the different species are mixed at the

molecular level. These species have the same convection velocity. In multiphase flows,

the different phases are mixed at the macroscopic scale. These phases have different

convection velocity. Many flows are multiphase multi-component flows.

Multiphase flows can be classified into

two categories:

- Dispersed flows, such as

bubbly, droplet, and particle flows

- Stratified flows, such as free

surface flows, or annular film flow in pipes.

A phase is considered dispersed if it

occupies disconnected regions of space—otherwise it is continuous.

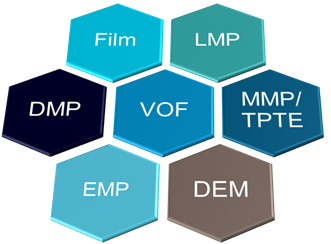

Simcenter STAR-CCM+

provides the following distinct multiphase models to meet the requirements of the two

main categories of flow:

| Model |

Key

Applications |

Example

Applications |

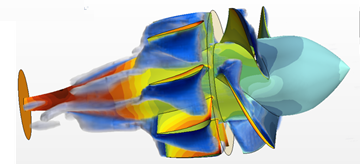

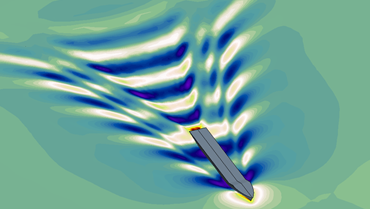

- Dispersed Multiphase (DMP)

-

Simulates flows of low loadings of particles

dispersed in a continuous phase (dilute multiphase

mixture) in a Eulerian manner. Provides a

lightweight alternative to the Lagrangian Multiphase

model. The conservation equations for mass,

momentum, and energy are solved for each dispersed

phase. The transport equations of the continuous

phase are solved by a single phase model.

The

DMP model is suitable for dispersed flows of

droplets, bubbles, and solid particles with low

volume fraction of the dispersed phase.

|

- Automotive Soiling

- Aerospace Icing

- Wet steam in low pressure steam turbine

stages

|

|

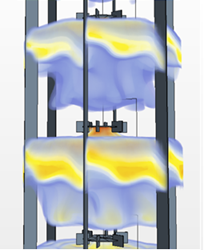

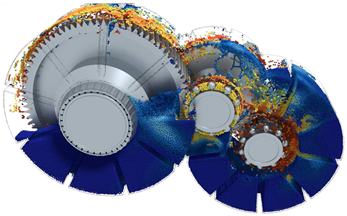

- Eulerian Multiphase (EMP)

- This

model, based on the concept of interpenetrating

continua, solves conservation equations for mass,

momentum, and energy for each phase. The phases share

the pressure field and the inter-phase interactions need

to be modeled to close the set of equations. Phase

interaction models are provided to define the influence

that one phase exerts upon another across the

interfacial area between them. The EMP model is used to

model the dispersed flows of bubbles, droplets, solid

particles, and for modeling a combination of dispersed

and stratified flows.

|

- Bubble Columns

- Mixing Vessels

- Settling Tanks

- Fluidized Beds

- Multiphase Separators

-

Stepped

Spillway

-

Multiphase

Pumps

-

Phase

Change equipments

|

|

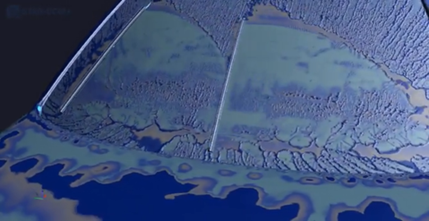

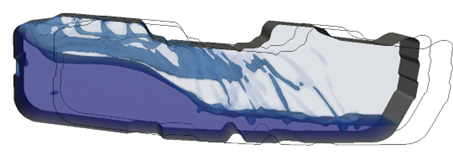

- Fluid Film

- Predicts

the dynamic characteristics of wall films using boundary

layer approximations and assumed velocity and

temperature profiles across the depth of the film. Film

transport is predicted using thin shells that lie across

the surface of solid walls on which the film is formed.

- The Fluid

Film model is suitable for stratified thin liquid film

flows over surfaces.

|

- Vehicle Rainwater Management

- Selective Catalytic Reduction (SCR)

- Fuel Sprays

- Lubrication

- Spray Coating/Deposition

- Aircraft Ice Protection

|

|

- Mixture Multiphase (MMP)

- A

simplified multiphase model that can be used to model

the flow of miscible phases. In this model, the

computational efforts are reduced by assuming the

multiphase mixture to be a homogeneous single-phase

system for which only one set of transport equations is

solved.

- The MMP

model is suitable for dispersed flows of mixtures of

bubbles in liquid or droplets in gas.

|

- Partially resolved gearbox/tank sloshing

- Multiphase pumps

- Fuel Cells

- Boilers

- Steam generators

|

|

- Two-Phase Thermodynamic Equilibrium

-

A

simplified multiphase mixture implementation, which

is designed for applications that involve two phases

of the same substance, typically water and steam,

which are in thermodynamic equilibrium.

The

Two-Phase Thermodynamic Equilibrium model is

suitable for dispersed flows of two thermodynamic

phases of the same material.

|

- Steam Generators

- Boilers

- Steam Turbines

|

|

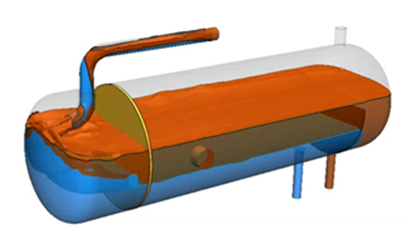

- Volume Of Fluid (VOF) Multiphase

-

Provided for systems containing two or more

immiscible fluid phases, where each phase

constitutes a large structure within the system

(such as typical free surface flows). This approach

captures the movement of the interface between the

fluid phases, and is often used for marine

applications.

The

VOF model is suitable for stratified flows (free

surfaces).

|

- Marine Hydrodynamics and Seakeeping

- Fuel Tank Sloshing

- Oil and Gas Flow Assurance

- IC Engine Cooling

|

|

- Discrete Element Method (DEM)

-

This

model is an extension of the Lagrangian framework.

Individual particles are modeled rather than

representative parcels and inter-particle contact

forces are explicitly accounted for. DEM is used to

model densely packed granular flows where particle

shape and collision behavior are important.

The

DEM model is suitable for dispersed flows of

discrete solid particles with high volume fraction

of the particles.

|

- Fluidized beds

- Rock mechanics

- Conveying aggregates

- Tablet coating

- Plugging fissures in oil wells

- Crop harvesting and lawn mowing

|

|

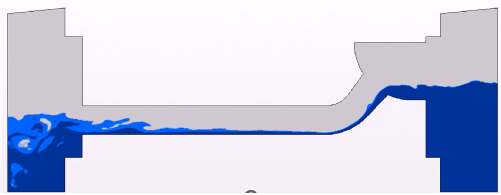

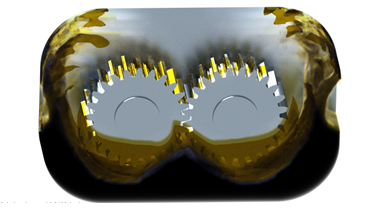

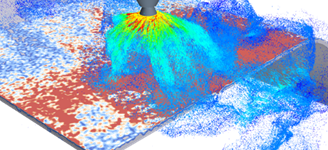

- Smoothed-Particle Hydrodynamics

(SPH)

-

SPH is a numerical method that

overcomes meshing-related constraints occurring with

mesh-based models, while still being based on the

Navier-Stokes equations.

Due to its Lagrangian characteristic and particle

approach, the SPH method can model a wide range of

applications involving dynamic flows with complex

interfaces.

SPH is particularly well-suited for

fast dynamic flows and complex boundaries, including

interfaces with fragmentations and reconnections

such breaking waves, jets and splashes, and moving

parts.

|

- Powertrain lubrication with oil bath

- Sloshing

|

|

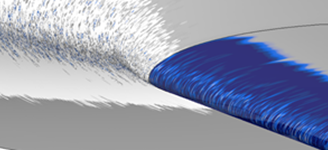

- Lagrangian Multiphase (LMP)

-

Solves

the equation of motion for representative parcels of

the dispersed phase as they pass through the system.

For the continuous phase, the conservation equations

for mass, momentum, and energy are solved. It is

intended for systems that consist mainly of a single

continuous phase carrying a relatively small volume

of solid discrete particles, droplets, or bubbles.

It is suited where the interaction of the discrete

phase with physical boundaries is important.

The

LMP model is suitable for dispersed flows of

discrete particles (bubbles, droplets, solid

particles) with low volume fraction of the

particles.

|

- Vehicle Water Management

- Cyclone Separation

- Erosion

- Aerosol Dispersion

- Liquid Fuel Combustion

- Spray Cooling

- Spray Coating

|

|

Simcenter STAR-CCM+

provides a selection of multiphase and phase interaction models to simulate a wide range

of multi-regime and multi-scale multiphase flows. In addition, hybrid modeling can be

used to model multiple flow regimes of a phase material by using a combination of

several different multiphase models.

A common framework has also been developed

to specify the models that define how pairs of phases interact with each other. These

models are known as phase interactions.

The multiphase models can also be used with the

complementary technologies available in Simcenter STAR-CCM+, such

as the population balance modeling to predict the size distribution of the dispersed

phase, adaptive mesh refinement (AMR) for providing a solution-refined mesh, and

adaptive time-stepping for automatic time-step adjustments.