Adjoint Shape Optimization: Surface Sensitivity for S-Bend

An adjoint shape optimization study requires a repeated sequence of steps in which the mesh is deformed according to a deformation field derived from the surface sensitivity. Simulation operations include specific steps that allow you to automate this workflow without requiring Java macros.

The geometry is an s-bend duct with incompressible air flowing through it. The flow enters the domain through a mass flow inlet boundary and leaves it through a pressure outlet boundary. The duct surface is divided into two parts - the original duct surface, which is optimized to reduce the total pressure drop of the duct and the extrusion wall which is not optimized.

In the simulation operation sequence, the primal flow is solved for 350 iterations. Afterwards you run the adjoint solver with surface sensitivity. The duct surface boundary is deformed using a morpher displacement as a function of the surface sensitivity and deepest descent, which is a factor you specify to limit the mesh deformation directly derived from the surface sensitivity. See also Setting Up a Shape Optimization using Surface Sensitivity.

Before executing the next loop of primal and adjoint solutions, the deformed mesh is checked against user defined criteria for mesh quality.

Additionally, to ensure a smooth shape optimization based on surface sensitivity, you apply a surface sensitivity filter to the tube geometry.

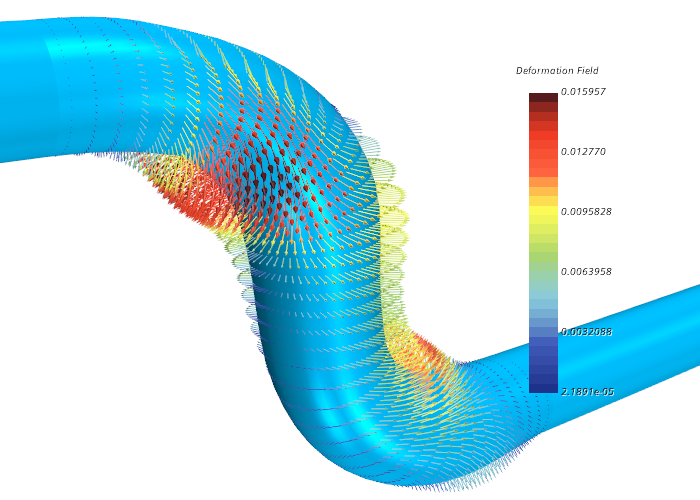

The deformation vector after several optimization cycle is as follows:

You require a double-precision version of Simcenter STAR-CCM+ to complete this tutorial.