Reacting Flow Applications

It is possible to model many different types of reacting flow applications using combinations of the reacting flow models that are provided in Simcenter STAR-CCM+.

The reacting flow general workflow describes how to begin modeling all types of reacting flow applications in Simcenter STAR-CCM+. See Reacting Flow General Workflow. Each specific type of reacting flow application follows an additional workflow, which you choose based on the specific application. A selection of common reacting flow applications and guidelines for selecting a suitable workflow are described in the following sections.

Gas Turbines

You can use either of the following workflows:

- Reacting Species Transport

Best for gas turbines at part load.

Use any of the following models:- Complex Chemistry (computationally expensive, so use only when necessary)

- when there is a mixture of multiple fuels

- to simulate flame ignition, quenching, or extinction

- to simulate slowly forming pollutants

- to simulate off-design load points

- Eddy Break-Up (EBU)

Use if the reactions are predominantly limited by turbulence and the mechanism is small (one or two steps), otherwise, use Complex Chemisty.

- Thickened Flame Model (TFM)

Useful for transient LES simulations. This model thickens flames artificially—which can help to reach a converged solution when the other flamelet models cannot.

- Complex Chemistry (computationally expensive, so use only when necessary)

- Flamelet

Best for gas turbines at full load or in which statistically-steady turbulent combustion occurs.

Use the Flamelet Generated Manifold (FGM) model.

See Flamelet.

Coal Combustion

- Interphase

Best for modeling interactions between the solid coal particles and the background gas, such as in coal furnaces. You can select either of the following models:

- Coal Combustion

Best for simulating coal furnaces. You can also model NOx emissions that are designed specifically for coal fuel.

- Particle Reaction

- Particle Combustion: to simulate particle combustion or char oxidation.

- Particle Devolatilization: to simulate particle devolatilization, gasification, or sublimation.

- Coal Combustion

- Reacting Species Transport

You can simulate multi-fuel combustion with the complex chemistry model.

- Flamelet

You can use the chemical equilibrium flamelet model for simulating simple coal combustion or fires.

See Flamelet.

Additionally, if required, you can model Emissions alongside the Flamelet or Reacting Species Transport workflows. The Interphase workflow provides the option to model specific NOx emissions.

Fluid Catalytic Cracking

Example application: gasoline production.

You can use one of the following workflows:

- Interphase

Best for modeling interactions between the liquid droplets and the background gas.

- Reacting Species Transport

You can simulate multi-fuel combustion with the Complex Chemistry model.

Polymerization

The Polymerization model allows you to simulate all relevant processes, including initiation, propagation, transfer, branching, scission, and termination.

You can use one of the following workflows:

- Polymerization

To simulate polymerization within a multi-component liquid (non-multiphase).

- Interphase Workflow: Multiphase

To simulate multiphase polymerization—for example, in a fluidized bed reactor or a stirred tank reactor—use the Polymerization model within a multi-component liquid phase of the Multiphase model.

See Polymerization.

Catalytic Convertors

Use the Reacting Species Transport workflow—which allows you to model transport of all species, with the additional Surface Chemistry and Emissions workflows.

See Reacting Species Transport, Surface Chemistry, Emissions.

You can specify the reacting surfaces as walls within solid regions or surfaces in porous regions.

Reacting surfaces

Use the Reacting Species Transport workflow—which allows you to model the transport of all species, with the additional Surface Chemistry workflow.

See Reacting Species Transport, Surface Chemistry.

If you want to monitor emissions, you can also use the Emissions workflow alongside the Reacting Species Transport workflow.

See Emissions.

The reacting surfaces can be walls within solid regions, or surfaces in porous regions.

Glass Furnaces

- Intraphase

You can use the Multiphase Volume of Fluid (VOF) model for simulating a reacting phase (which uses a Flamelet model or Reacting Species Transport model) within a flow of several immiscible fluid phases.

See Intraphase.

- Reacting Species Transport

- Eddy Break-Up

Use if the reactions are predominantly limited by turbulence and the mechanism is small (one or two steps).

- Complex Chemisty

Use with a Chemkin formatted mechanism.

- Eddy Break-Up

- Flamelet

You can use the Steady Laminar Flamelet model for steady state opposed flow diffusion flames with tabulated detailed kinetics.

See Flamelet.

If you want to monitor the emission levels of particular species, you can additionally use the Emissions workflow.

See Emissions.

Furnaces and Burners

- Flamelet (use with tabulated detailed kinetics)

- Steady Laminar Flamelet

for steady state opposed flow diffusion flames.

- Flamelet Generated Manifold

Suitable for all premixed or partially premixed flames where the flamelet assumption is valid (there are infinitely fast chemical reactions). Use if you want to capture ignition, extinction, or quenching.

See Flamelet.

- Steady Laminar Flamelet

- Reacting Species Transport

(Use if none of the flamelet models are suitable)

- Complex Chemistry

Use with a Chemkin formatted mechanism, for transient calculations, ignition, and extinction.

- Eddy Break-Up

Use with one or two simple reactions that you define in the GUI.

- Complex Chemistry

If you want to monitor the emission levels of particular species, you can additionally use the Emissions workflow.

See Emissions.

Reacting Channels

Use the Reacting Channels workflow which describes how to set up the reacting channels and surrounding firebox volume.

See Reacting Channels.

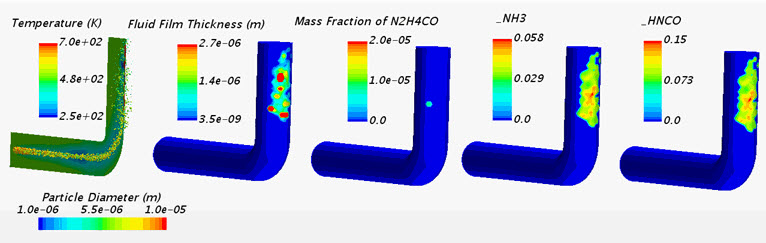

Fluid Film Reactions

Example application: trickle-bed reactors or selective catalytic reduction (SCR) reactions in urea film.

You can simulate reactions within a fluid film (intraphase) using the Reacting Species Transport workflow with the optional model, Fluid Film. You use the Multi-Component Gas model for the background fluid region, and interface the gas with a fluid film shell region.