Loading the Starting File and Setting Up Physics

For this tutorial, you are provided with a starting simulation that contains predefined mesh operations that generate a structured volume mesh. This type of mesh is suitable for turbomachinery applications..

- Open a double precision version of Simcenter STAR-CCM+ and select .

- In the Load a File dialog:

- Set Process Options to Serial.

- Click Browse.

- In the Open dialog, navigate to the designExploration folder of the downloaded tutorial files and select the file Stage37_smartsweep_start.sim.

- Click Open, then OK.

-

For the continuum, right-click the node, select the following models

in order:

Group Box

Model

Space

Three Dimensional

Time

Steady

Material Gas Flow Coupled Flow

Gradients (Selected automatically)

Equation of State Ideal Gas

Energy Coupled Energy (Selected automatically) Viscous Regime

Turbulent

Reynolds-Averaged Navier-Stokes (Selected automatically)

K-Omega Turbulence

SST (Menter) K-Omega (Selected automatically)

Wall Distance (Selected automatically)

All y+ Wall Treatment (Selected automatically)

Optional Models

Cell Quality Remediation

Solution Interpolation

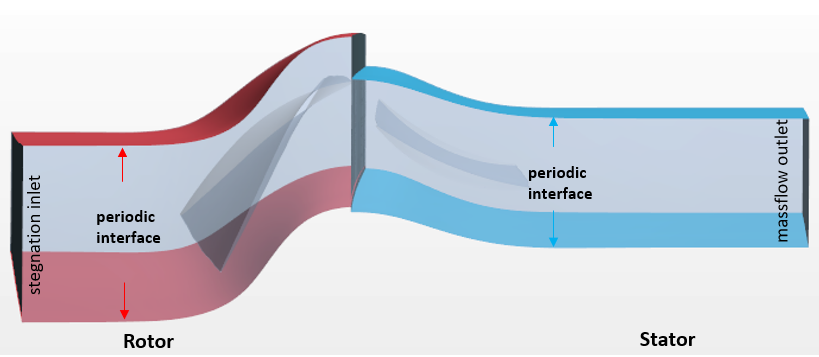

The region topology and interface settings are shown below:

-

To set the boundary conditions:

-

To define the interfaces:

-

You set a moving reference frame for the rotor region. Moving reference frame provides

a time-averaged solution for a rotating object. In this way the simulation can run steady

without considering the transient effect and moving the mesh vertices. To define the

rotation of the rotor, you create a rotating reference frame:

- Save the reference simulation as Stage37_smartsweep_ref.sim