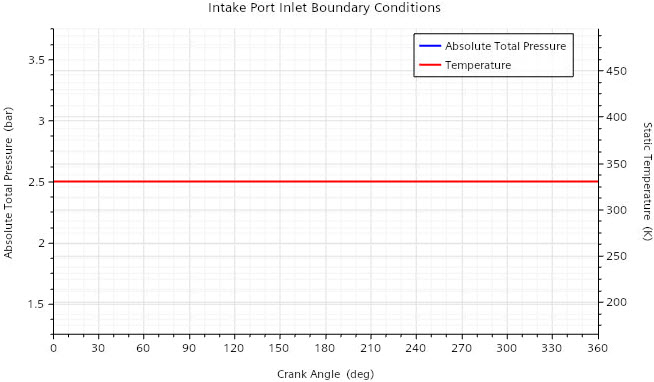

Air enters through the intake port inlet with a static temperature of 330 K

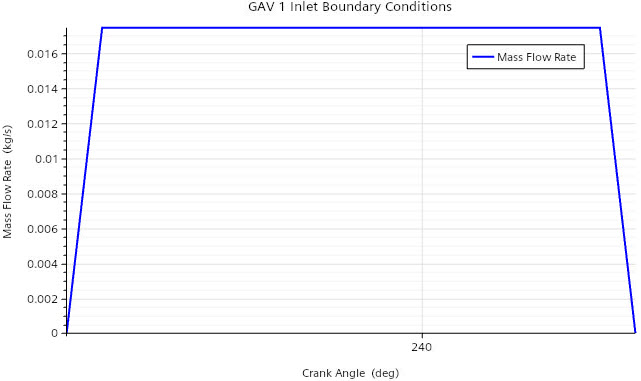

and a pressure of 2.5 bar. At the inlets of the GAVs, you introduce methane gas with a total

temperature of 330 K, where the gas admission starts at 230.0 deg CA and ends at 246.0 deg CA.

You import a table that describes the mass flow rate of the methane gas as a function of crank

angle. To avoid diffusion of flow quantities at the GAV inlets, you exclude the flow-boundary

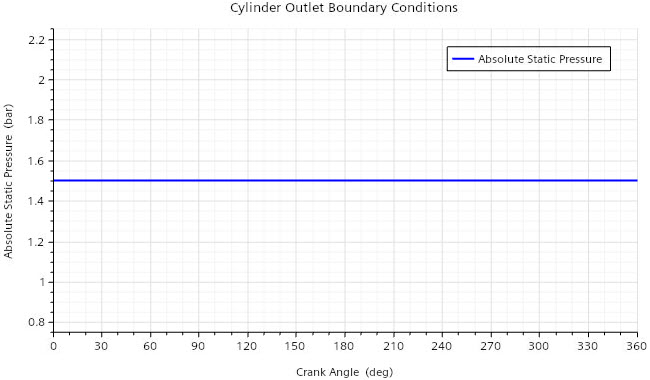

diffusion fluxes. At the exhaust port outlet, you set a pressure of 1.5 bar and a static

temperature of 700 K.

To set the boundary conditions: -

Set the inlet boundary conditions for the intake port:

-

Right-click the node and select Edit.

-

Within the Edit dialog, in the

Pressure group box, click

Import.

-

In the Import Table dialog,

navigate to the inCylinder folder of the downloaded tutorial

files, select twoStrokeEngine_IntaketPort_Inlet.csv, and click

Open.

In the Graphics window, a plot opens that displays the a constant

pressure of 2.5 bar for all crank angles. The correct table columns and units for the

pressure are assigned automatically.

-

In the Static Temperature

group box, from the File drop-down menu, select twoStrokeEngine_IntaketPort_Inlet.

-

Set Temperature Column to T_K.

The plot in the Graphics window

updates to add the temperature data—a constant temperature of 330 K for all crank

angles.

The correct species mass fractions for the inlet are set by default.

-

Click Apply, then Close.

-

Set the inlet boundary conditions for the GAVs:

-

Right-click the node and select Edit.

-

Within the Edit dialog, in the Boundary group box, set

Type to Mass Flow

Inlet.

-

In the Total Temperature

group box, select Constant from the drop-down menu, then set the

constant value to 330.0 K.

-

In the Mass Flow Rate

group box, from the drop-down menu, select Table, then click Import.

-

In the Import Table dialog,

navigate to the inCylinder folder of the downloaded tutorial

files, select twoStrokeEngine_GAV_Inlet.csv, and click

Open.

The correct table columns and units are assigned automatically.

In the Graphics window, a

plot opens that displays the mass flow rate as a function crank angle.

-

In the group box, set the following properties:

| Property |

Setting |

| Air Mass

Weighting |

0.0 |

| Exhaust Mass

Weighting |

0.0 (default) |

| Fuel Mass

Weighting |

1.0 |

-

Click Apply, then Close.

-

Repeat Steps 2 a - f for the node.

-

Exclude the flow-boundary diffusion fluxes:

-

In the Explorer pane, select the Simulation tab.

-

In the simulation tree, expand the node.

-

Select the following nodes in order and deactivate Flow Boundary Diffusion:

- Segregated Flow

- Segregated Fluid Enthalpy

- ECFM-3Z

- Conditional Enthalpy

-

Select the In-Cylinder tab.

-

Set the outlet boundary condition for the exhaust port:

-

Right-click the node and select Edit.

-

In the Edit dialog, in the Pressure

group box, click Import.

-

In the Import Table dialog,

navigate to the inCylinder folder of the downloaded tutorial

files, select twoStrokeEngine_ExhaustPort_Outlet.csv, and click

Open.

In the Graphics window, a plot opens that displays a constant

pressure of 1.5 bar for all crank angles.

-

Click Apply, then Close.

-

Save the simulation

.

.

.

.