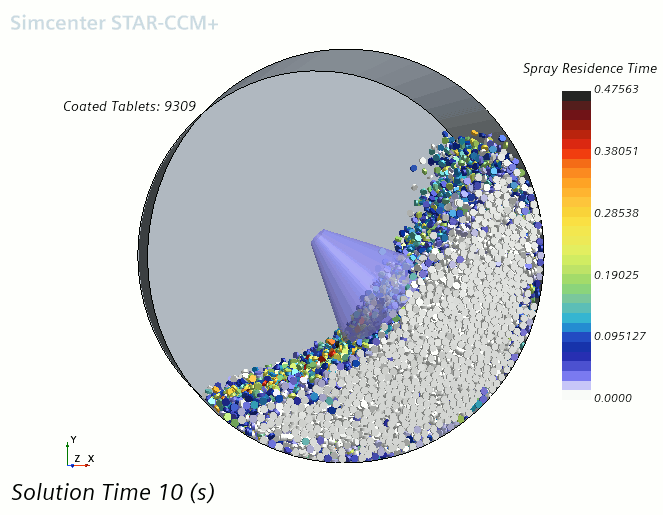

Cylindrical Particles in a Rotating Drum

This tutorial simulates a large number of cylindrical-shaped tablets tumbling in a rotating drum and being sprayed with a protective coating.

The tablets are simulated by cylindrical DEM particles. The tablets are injected into the rotating drum and, once they have settled, their residence time within the conical spray is tracked. The complexity of the coating process is avoided by assuming that all tablets are coated in a uniform manner when within the spray, regardless of their angle relative to the jet. The transfer of the coating to, or from, tablets and mixer walls is ignored, as is the effect of the spray jet and drag on the tablets due to the air in the drum. However, the impact between tablets and drum-walls (including frictional effects), is included via a set of phase-interactions.

This tutorial consists of two simulation runs. In the first run, the tablet particles are injected into the drum, which rotates for three seconds (approximately one full drum reveolution) to settle the particles. In the second run, the passive scalar is activated and the drum rotates for a further seven seconds to track the coating process.

Note that, although the laminar flow solver is selected in this example, the fluid flow solver is switched off (frozen). Thus, the air in the drum is assumed to be still and so to have negligible effect on the movement of the tablets.