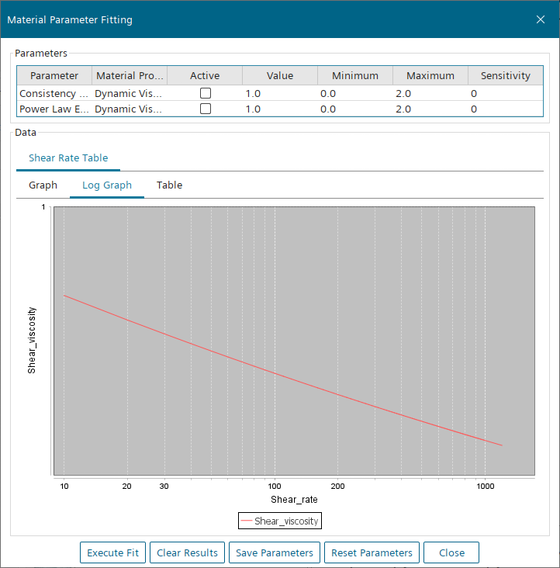

The Material Parameter Fitting Dialog

Use the Material Parameter Fitting dialog to derive model parameters from experimental rheological data in tables under the Material Calibration model.

- Parameters pane

- Lists a line for each term

exposed for a material property method associated with the active rheology

model. See Material Property Methods for Rheology.

- Parameter column

- Lists the properties of nodes available to the Fitting Tool.

- Material Property column

- Lists the names of nodes available to the Fitting Tool.

- Active checkbox

- When selected, indicates the parameter is available to derive model parameters.

- Value column

- Lists the current values for the parameters, determined according to the procedure described in Calibrating Non-Newtonian Model Parameters.

- Minimum and Maximum columns

- Define the fitting bands for the parameters, determined according to the procedure described in Calibrating Non-Newtonian Model Parameters.

- Sensitivity column

-

Reports parameter sensitivity with respect to the optimized function. The value is reported as computed by the fitting engine when the fit is executed.

For inactive parameters the value is always zero. The value ranges from 0 to 1 and can be used as an indicator of the influence of a specific parameter on the result of the fit, with 1 having the most influence. Parameters with sensitivities close to 0 can be disabled during the fitting; for complex polymers with many parameters, this can accelerate the fitting process.

- Graph tab

- Displays a graph of the data.

- Log Graph tab

- Displays a log-log graph of the same data.

- Table tab

- Displays the raw numerical data.

- Execute Fit button

- Invokes the curve-fitting algorithm using the provided initial values to find the best-fit model parameters.

- Clear Results button

- Deletes the Result curves displayed on the Graph and Log Graph tabs.

- Initialize Parameters button

- Used with the Viscoelastic rheology model. Sets the Value, Minimum, and Maximum initial values based on the Frequency - G' G" table under . Also writes a message in the Output window, suggesting the number of viscoelastic modes to use.

- Save Parameters button

- Saves the new values to the Material Properties nodes under the Liquid model.

- Reset Parameters button

- Restores edited parameters to their initial values (continuum values) or the last saved values.

- Close button

- Closes the dialog.