Preparing and Generating the Mesh

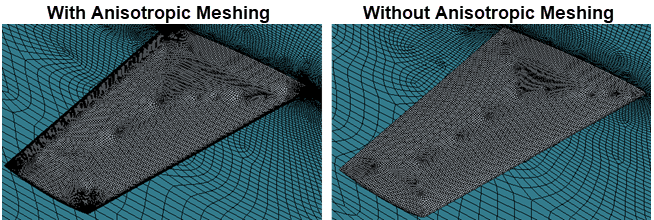

After assigning parts to regions and setting the boundary types, you can define the mesh settings for the volume mesh. For this simulation, you generate an anisotropic and aligned volume mesh based on an initial quadrilateral surface mesh.

The polyhedral mesher is used in conjunction with the advancing layer mesher to build a suitable mesh for the fluid volume. In order to resolve the boundary layer, the number of prism layers is set to 20 and the prism layer near wall thickness is set to a value consistent with y+ ~ 1. For external aerodynamic cases, 20-30 prism layers are typically used.

-

To set up the volume mesh:

-

Edit the node, click Expand/Contract Tree, and set

the following properties:

Node Property Setting Base Size Value 0.2 m Minimum Surface Size Percentage of Base 15.0 Surface Growth Rate Surface Growth Rate Slow Number of Prism Layers Number of Prism Layers 20 Prism Layer Near Wall Thickness Prism Layer Near Wall Thickness 1.55E-6 m Prism Layer Total Thickness Size Type Absolute Absolute Size 0.005 m -

As flow behavior far from the wing is not particularly important for this

simulation, you can specify a coarser mesh on the far-field. To do so:

-

To capture the turbulent flow conditions that occur behind the wing, set up a

wake refinement control:

-

To use anisotropic meshing:

-

To refine the mesh on the leading edge:

-

To refine the mesh on the side:

-

To refine the mesh on the trailing edge:

-

Click

(Generate Volume

Mesh) in the toolbar or select Generate Volume

Mesh in the Mesh menu.

(Generate Volume

Mesh) in the toolbar or select Generate Volume

Mesh in the Mesh menu.

The run and progress of the meshers are displayed in the Output window.

-

To display the volume mesh, from the Vis

toolbar, click

(Create/Open Scenes) and select

Mesh.

(Create/Open Scenes) and select

Mesh.

- Save the simulation.