Running the Simulation

To reduce the run time, you only run the simulation for one full rotation of the rotor. This means running for 360 time-steps. In industry, it is typical to run over a large number of revolutions to ensure you obtain a converged result.

- Select the node and set Morph From Zero to Enabled.

To improve accuracy, decrease the tolerance for mesh

morphing:

- Select the and set Morpher Tolerance to 1.0E-10.

-

Select the node and set the following properties:

Porperty Time-Step ${Xperiod}/${Xsteps_per_rev} Temporal Discretization 2nd-order - Select the set Maximum Steps to 360.

-

Click

(Initialize Solution) in the toolbar.

Initializing the solution triggers Simcenter STAR-CCM+ to read through the input files and import the beam mesh.

(Initialize Solution) in the toolbar.

Initializing the solution triggers Simcenter STAR-CCM+ to read through the input files and import the beam mesh. -

To run the solution, click

(Run).

(Run).

- When the simulation has finished running, save it.

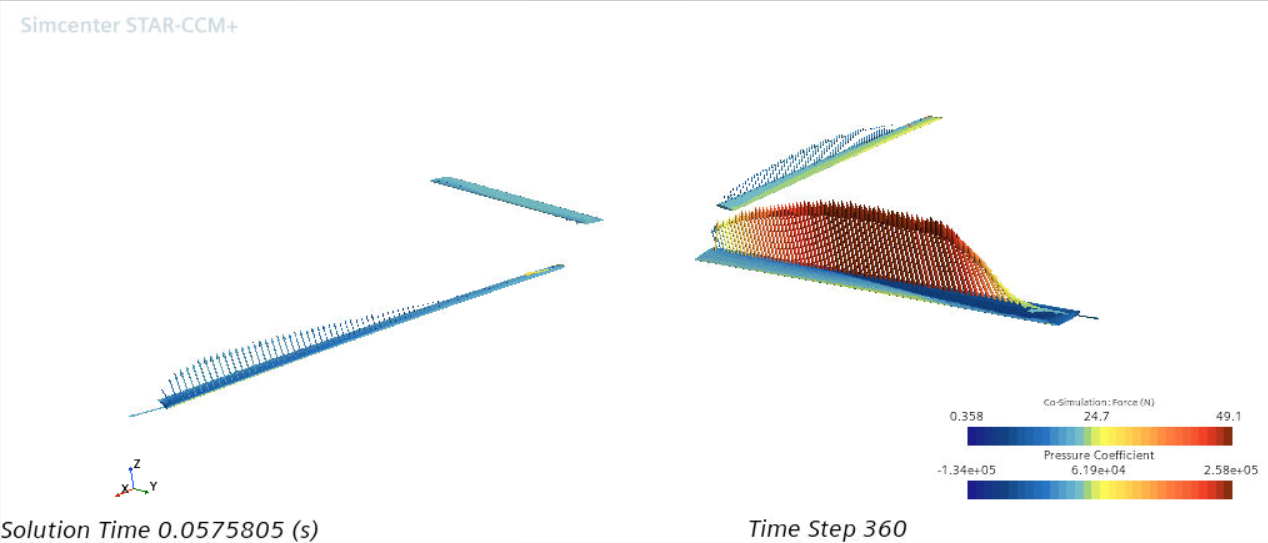

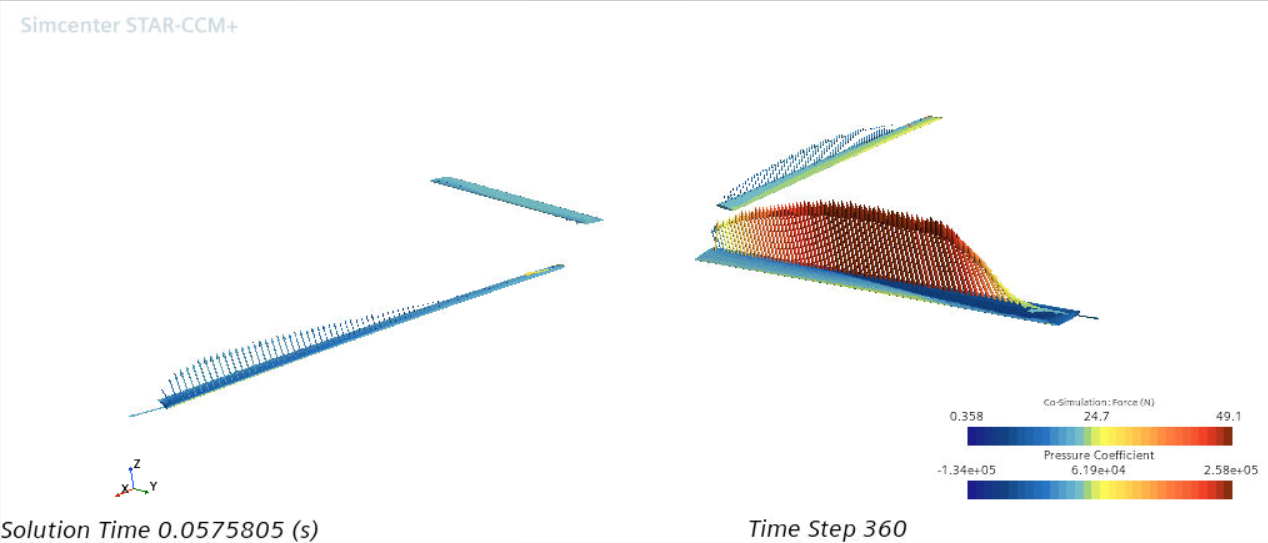

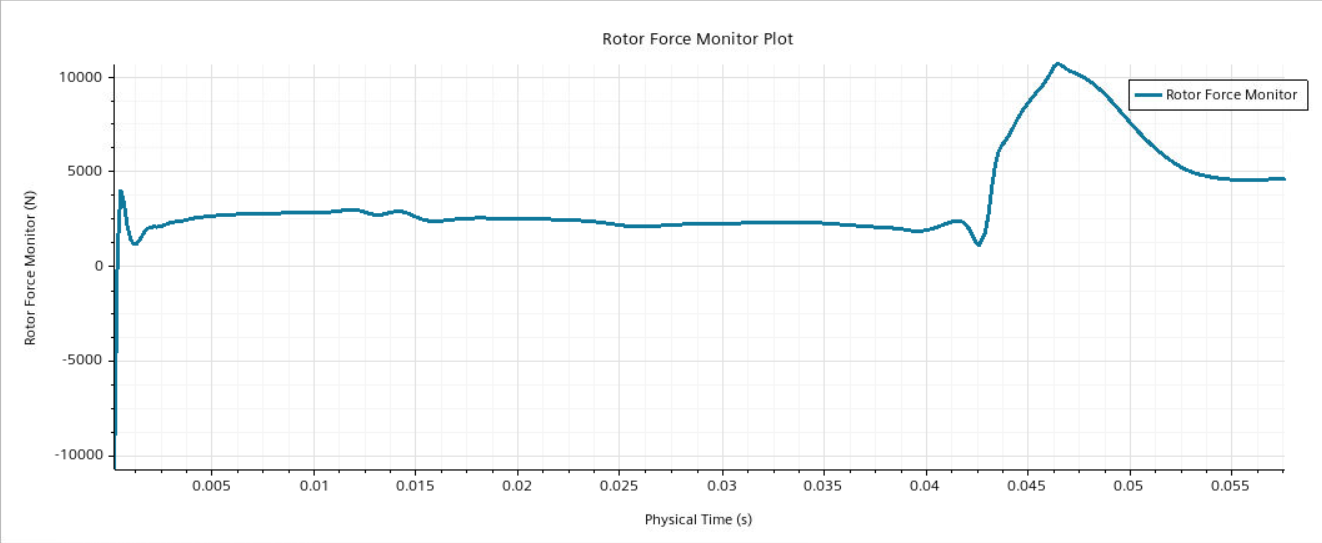

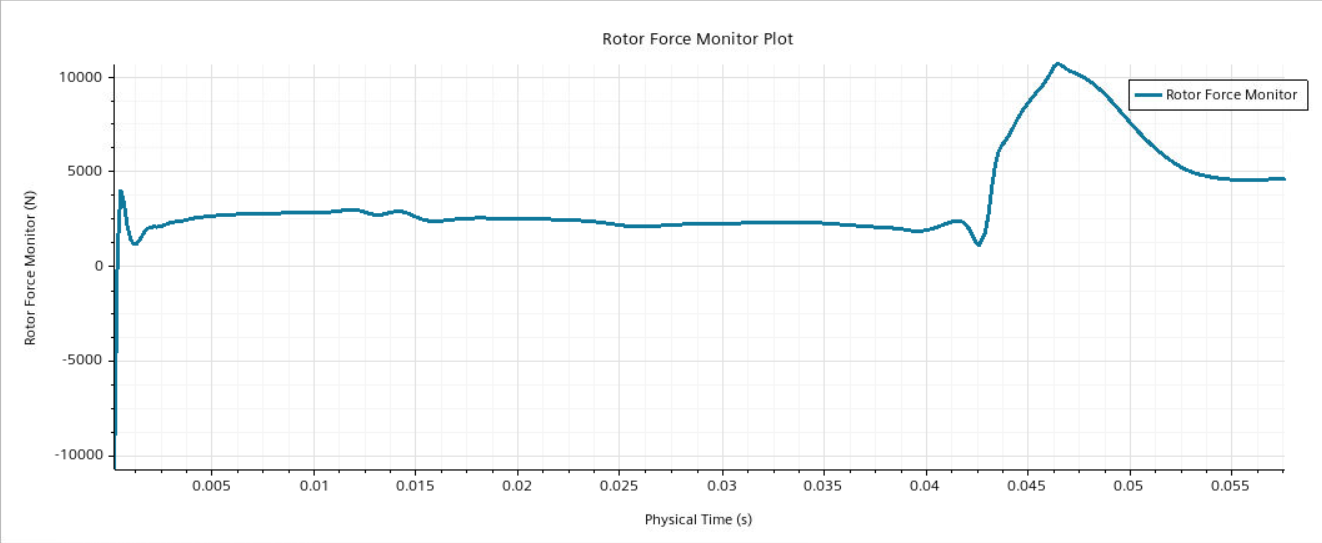

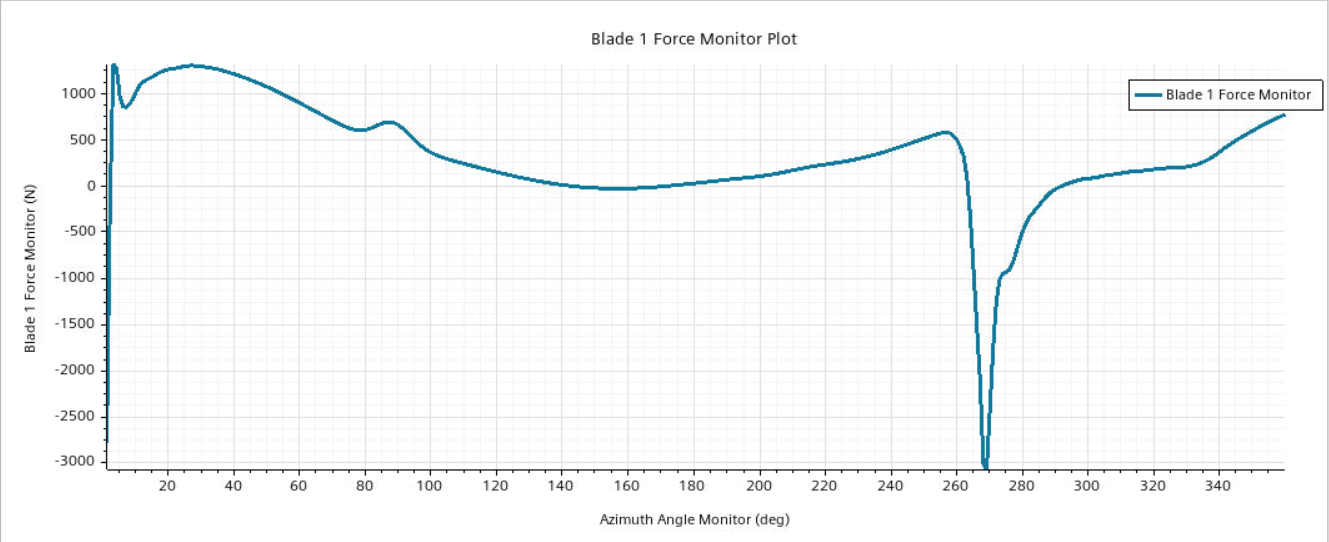

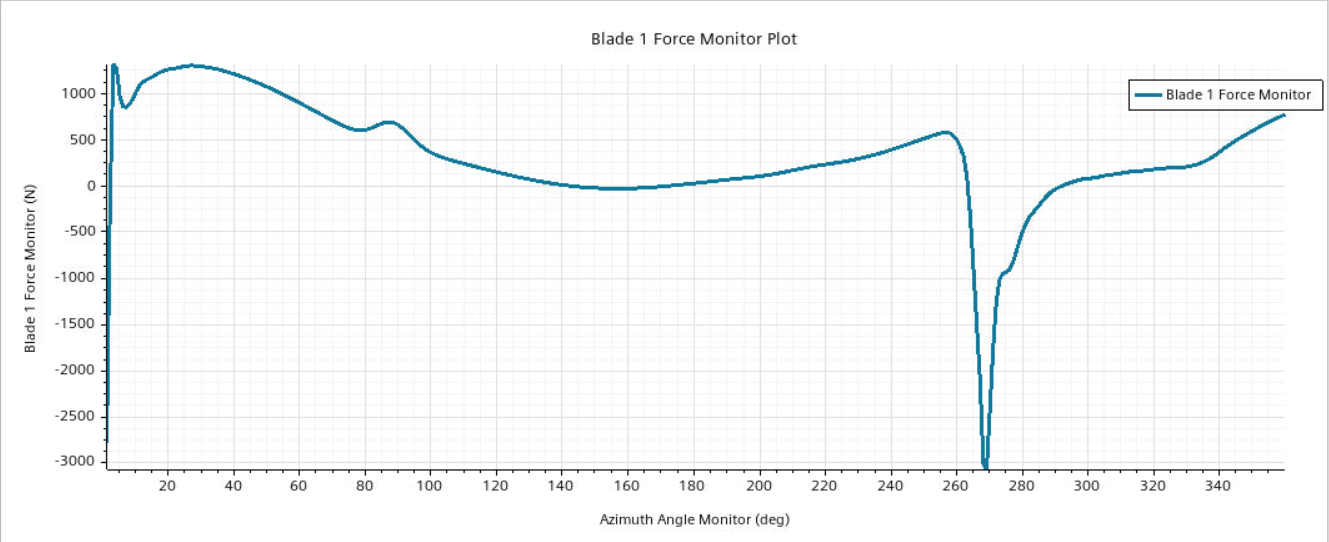

The scenes and plots appear as follows:

Force and

Pressure

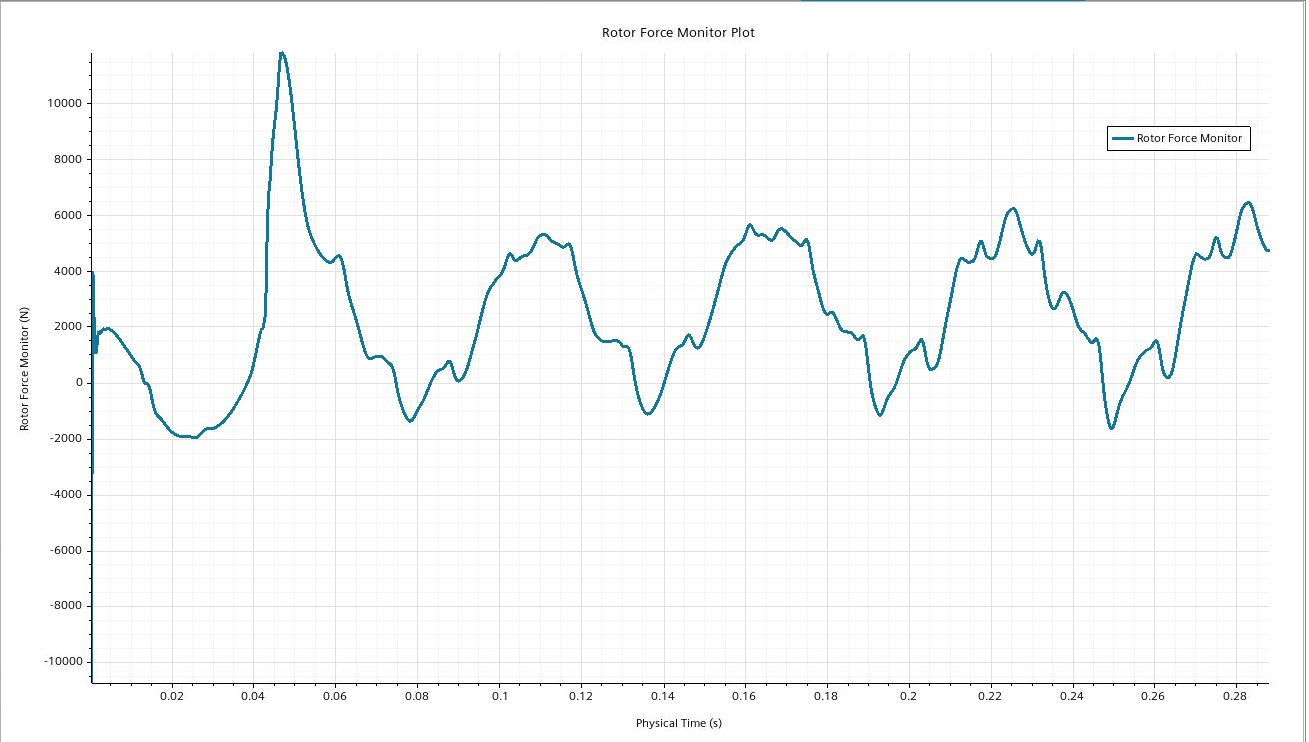

Rotor Force Monitor

Plot

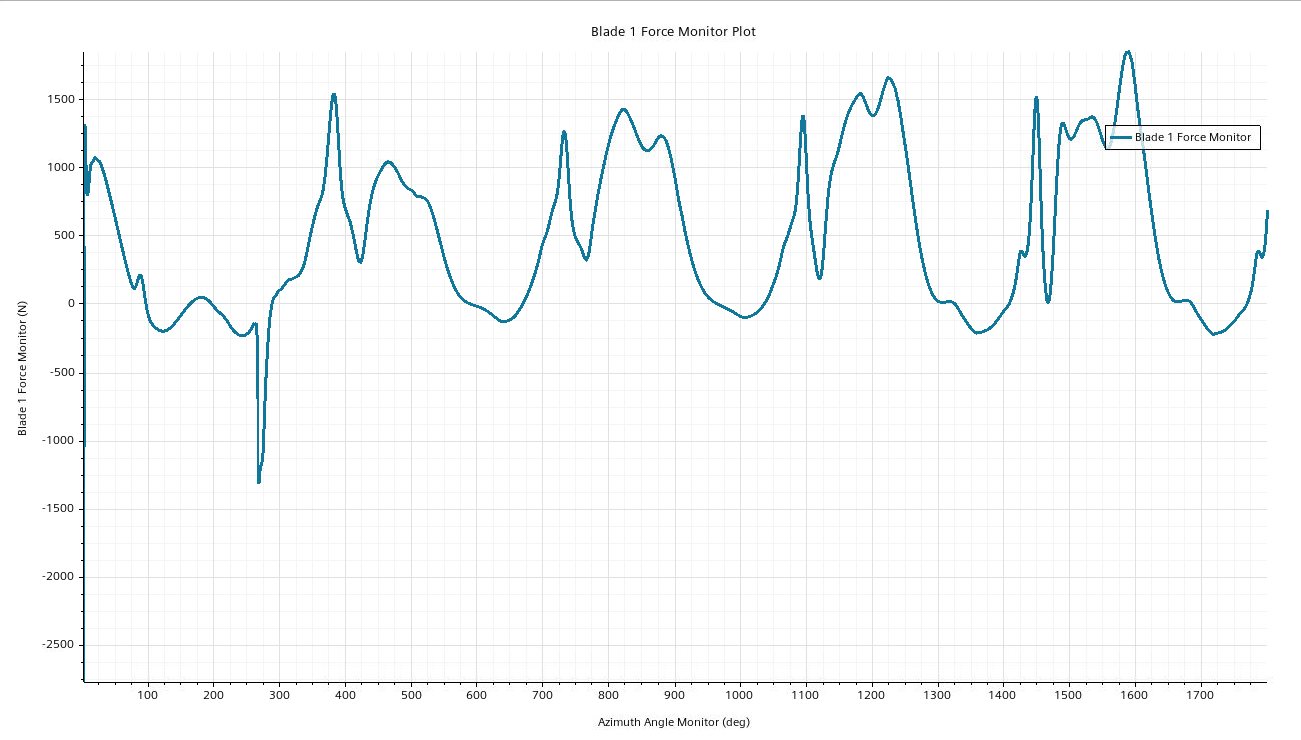

Blade 1 Force Monitor

Plot

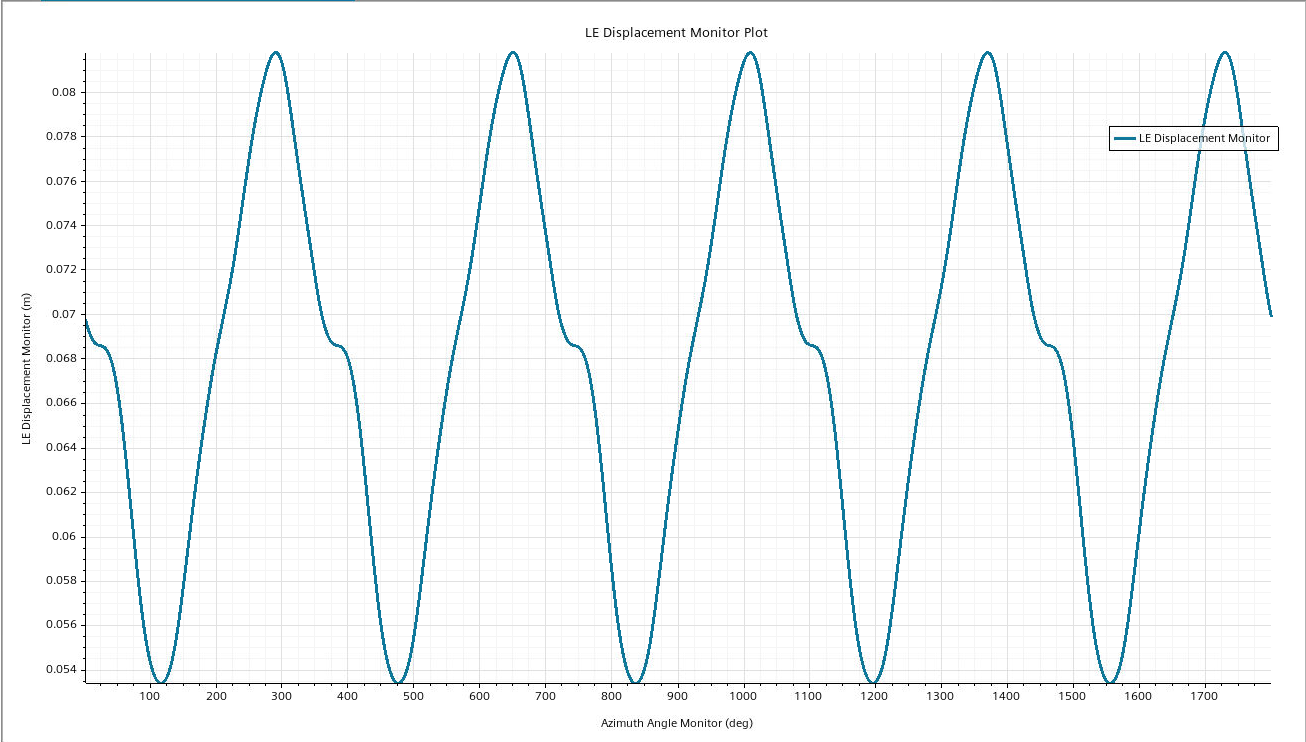

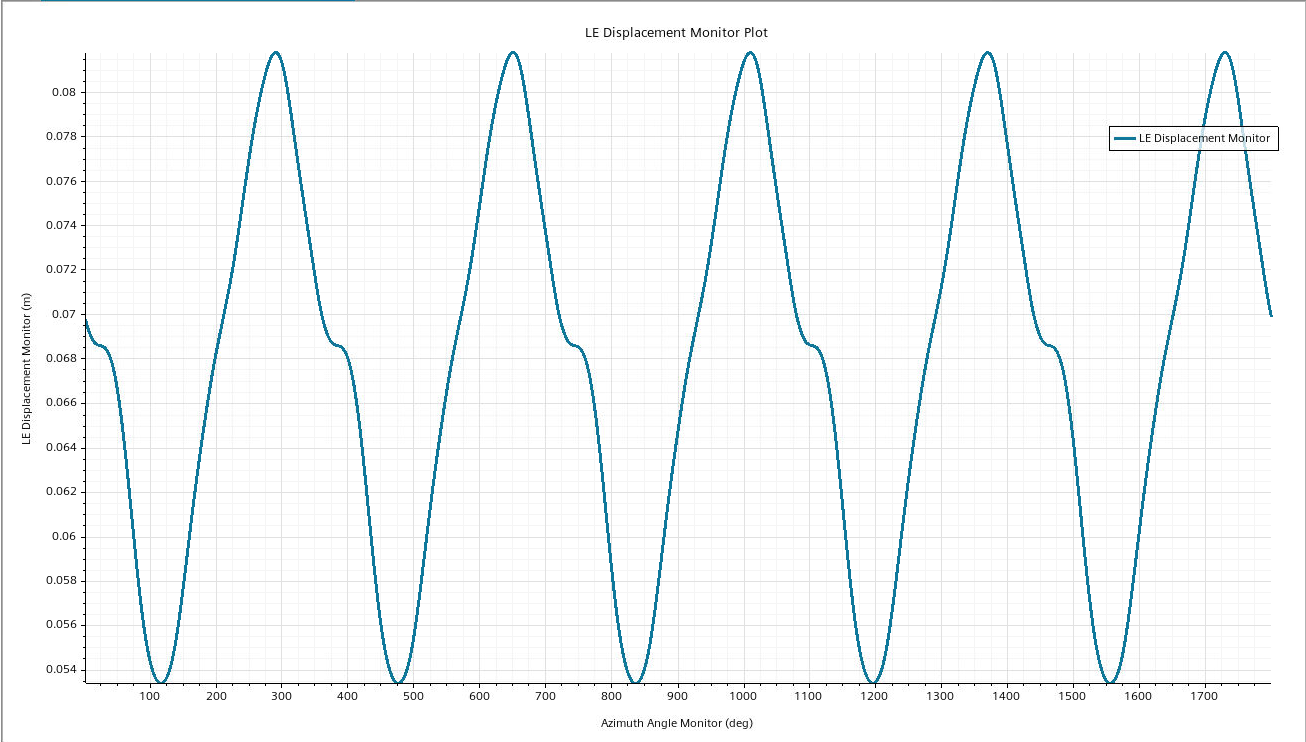

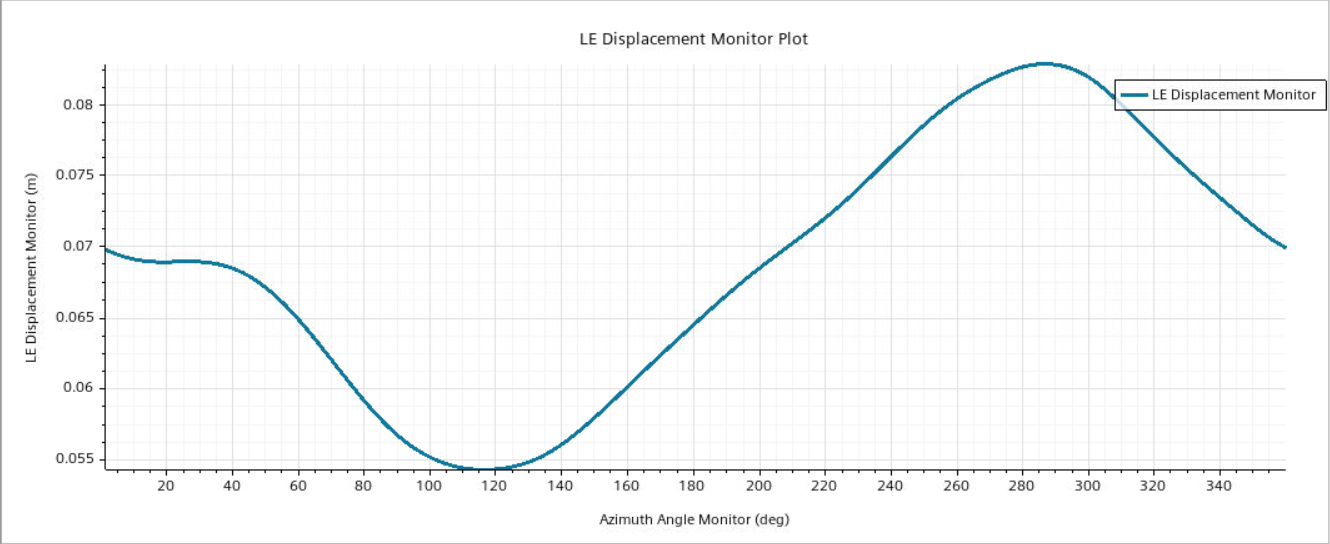

LE Displacement Monitor

Plot

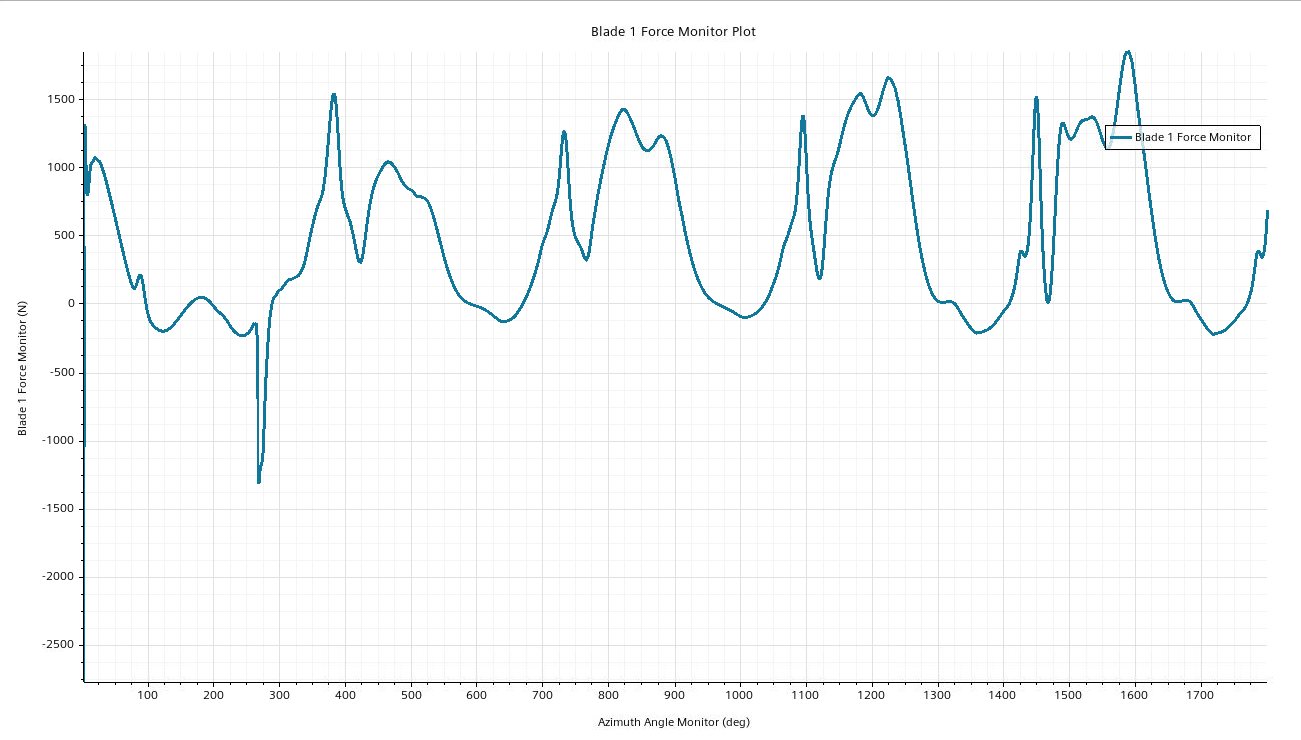

As you only run the simulation for one full rotation, it is likely the results are not converged. However, due to the large number of time-steps required, it can be computationally expensive and time consuming to obtain a converged rotor blade aeroelasticity study. Below are the plots after 5 rotations (1800 time-steps) for comparison:

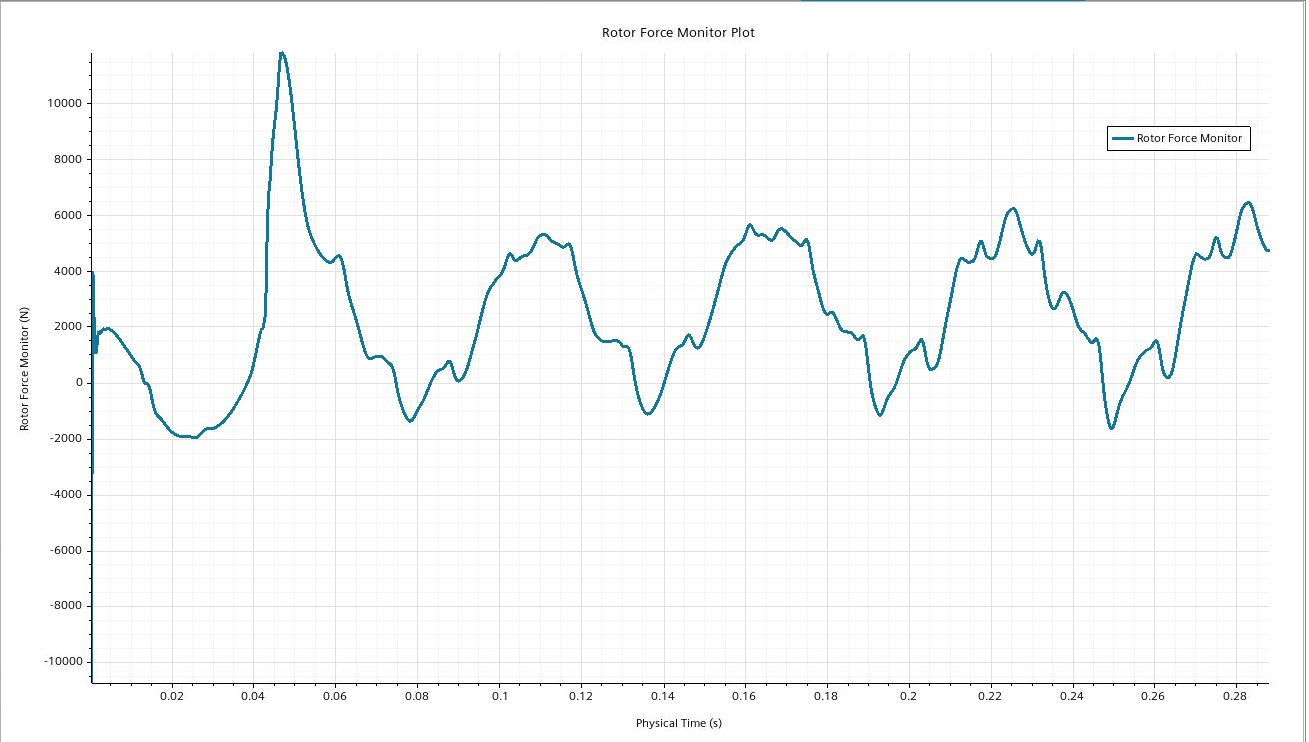

Rotor Force Monitor

Plot

Blade 1 Force Monitor

Plot

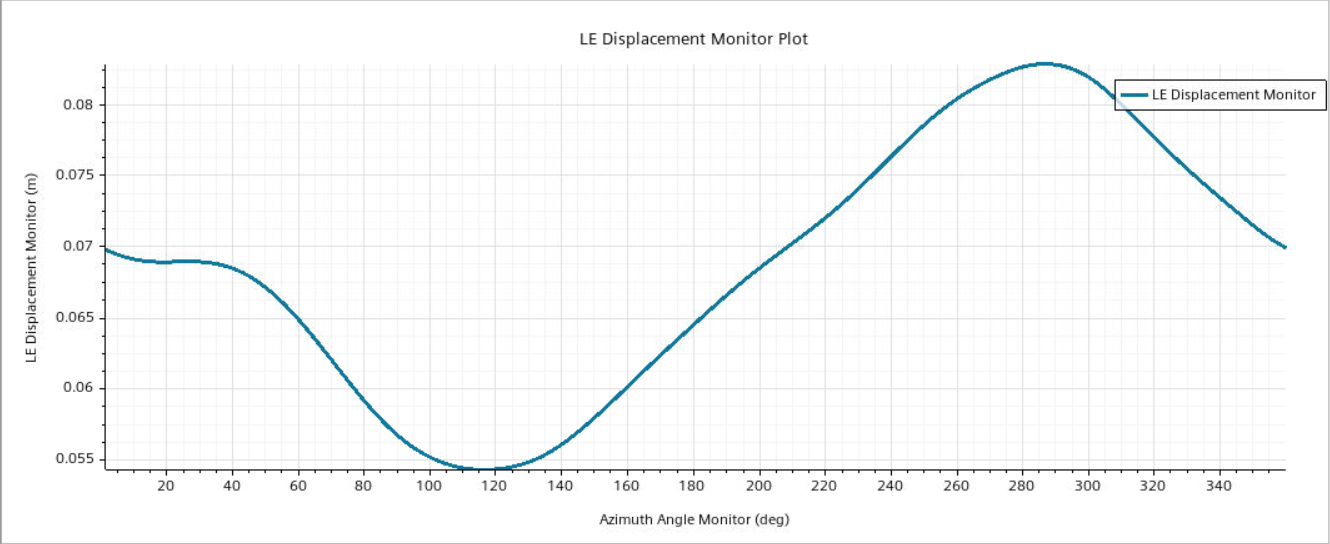

LE Displacement Monitor

Plot